Manufacturers, warehouses, and other companies that can master how to secure a load to a pallet can significantly reduce instances of lost or dam- aged products. This guide offers tips on securing a pallet and the best products to enhance your operations.

When typical pallet stacks weigh thousands of pounds, properly securing loads on pallets is essential. Attention to detail will help prevent employee injury and product loss. Consider these tips for how to secure a load to a pallet.

What’s the Importance of Securing Pallet Loads?

As a company, you understand that properly securing loads on pallets is essential to the safety of your products and your employees. Companies need to know how to strap a pallet for several reasons, including the following.

- Protecting Products

Properly securing pallet loads helps protect your prod- ucts during shipping and transportation. A secured pallet will remain upright and stable while on a truck or train, providing security for products. Securing pallets also saves businesses money, preventing losses due to damage from products sliding off the pallet. - Ensuring a Safe Workplace

Businesses must ensure compliance with the safety standards put out by the federal Occupational Safety and Health Administration (OSHA). While OSHA does not have specific safety regulations regarding how to secure a pallet load, general safety rules still apply.

For example, OSHA’s General Duty clause requires employers to provide a workplace free of any hazards likely to cause death or severe injury. Improperly loaded pallets and pallet racks can certainly cause serious injuries. Businesses can avoid this occupational hazard by correctly securing loads on pallets to prevent unstable pallets.

8 TIPS FOR HOW TO SECURE A PALLET

1. COVER THE ENTIRE PALLET

Products should always cover the entire pallet. Loading the whole pallet provides stability and prevents items from swaying or toppling during transit. Covering the pallet’s whole surface is especially important when loading the bottom of the pallet. An uneven bottom layer allows products to shift and fall off, resulting in damage. Always load the entire surface of the pallet for the safest results.

2. ENSURE PALLETS ARE IN GOOD SHAPE

A pallet is the foundation of each load. The foundation must be in good shape to keep the stack stable and upright. Before loading a pallet, ensure the pallet is the right size and strength to support the load. Check for cracks, loose boards, protruding fasteners, and any other signs of deterioration. If the pallet is damaged, discard it and use one in better shape.

3. LOAD PALLETS EVENLY

Evenly stacking products and materials is essential. An evenly stacked pallet provides greater balance, stability, and strength to the whole stack. It also reduces the pallet’s likelihood of falling during shipping or in the warehouse. Ensure you distribute your loads evenly on the pallets to efficiently use space and reduce the chances of a pallet stack falling over.

4. CHECK FOR GAPS

Eliminate gaps in a pallet load for enhanced security. If a pallet moves too much during shipping or handling, items can fall into openings on the stack. An appropriately secured pallet will fit tightly and move as a single unit. Check for gaps as you load each pallet. The items on a load should fit snuggly together, leaving little space in between.

5. PLACE HEAVIER ITEMS ON BOTTOM

Ensure that you load heavier items toward the bottom of the stack. Pack your pallets so that they taper inward as they rise. Placing sturdier, heavier items at the bottom will keep the pallet’s center of gravity closer to the ground, preventing the pallet from falling and products from settling.

Loading heavier items on the bottom also keeps lighter products safe. Pack more delicate items toward the top to protect them from being damaged by heavier products.

6. FOLLOW A STACKING PATTERN

While loading a pallet can require some creative stacking, you should always follow a stacking pattern when you load items. Fitting products together in a fixed way helps increase the load’s stability and balance. This practice can also im- prove warehouse safety by eliminating over- hanging edges and uneven weight distribution.

Here are a few common stacking patterns you might use:

🡢 Column-aligned: In this method, you place one item on another to create a cube.

🡢 Interlocking: Interlocking items in a pinwheel shape involves intertwining layers together.

🡢 Brick: In brick stacking, each item goes on top of another at a 90-degree angle.

7. STACK YOUR PALLETS UPRIGHT

It’s also essential to stack pallets properly. Stacking pallets on their sides can weaken their structure, causing them to splinter or crack. Always stack pallets flat, whether they’re loaded or unloaded.

8. ENSURE PROPER BINDING TO THE PALLET

Binding the products to the pallet is essential for securing loads on pallets. Attach the entire load down to the bottom of the pallet to bind it to its foundation. When you’ve correctly bound your pallet, it will travel as a unit when you move it.

Why use pallet strapping to secure loads?

Businesses can choose from several pallet-securing products to keep their loads in place. Some of the top methods are pallet wrapping and plastic stretch film, which use plastic film to wrap loads. However, a third option rises above these two methods — pallet strapping.

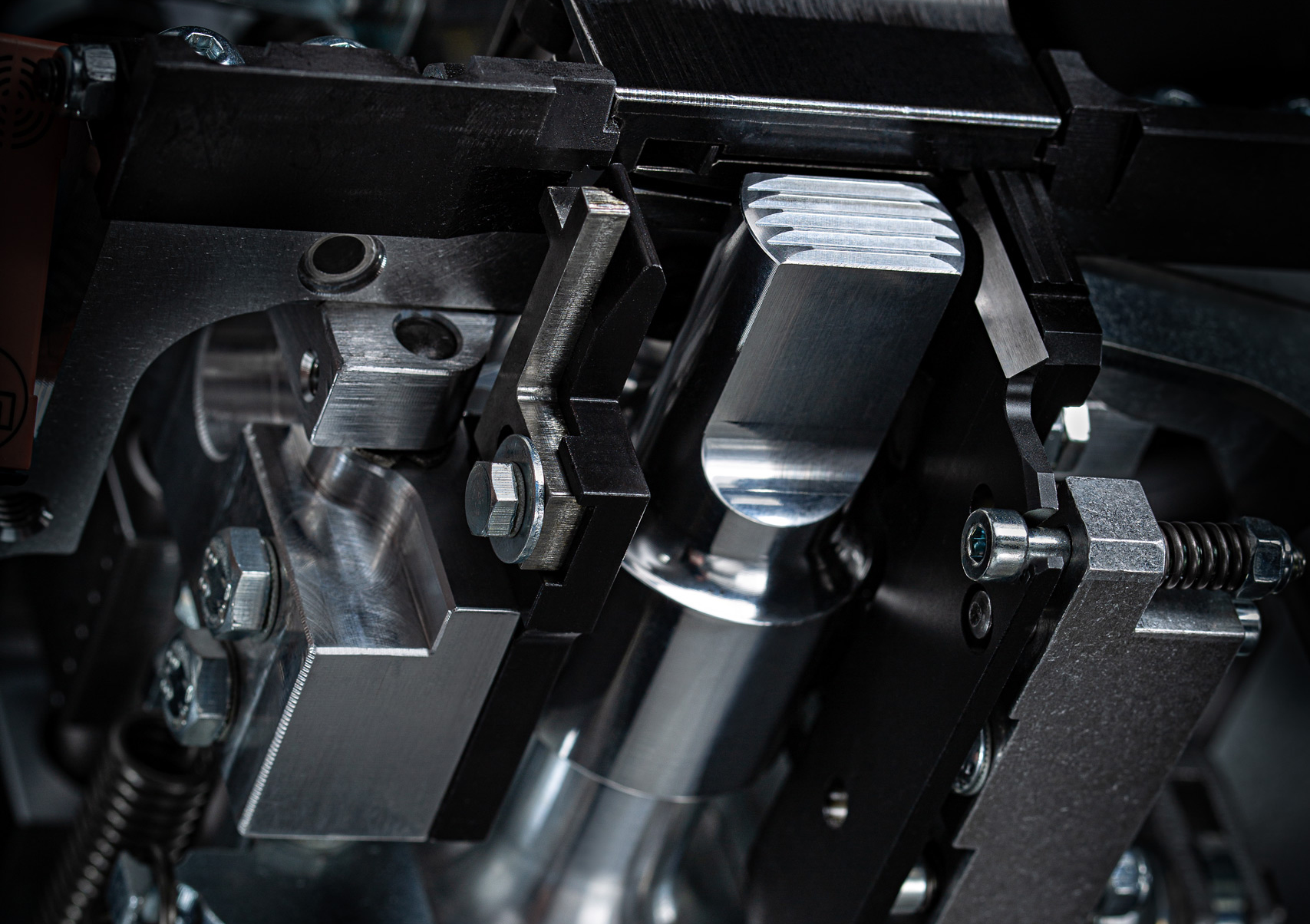

Pallet strapping uses a strapping machine to strap the load onto the pallet quickly. These ma- chines are compatible with very large pallet loads and those with uneven sides, giving them greater versatility.

Pallet strapping offers the following advantages:

🡢 Faster strapping:

Automation makes pallet strappers capable of high performance. Pallet strapping machines are faster than automatic pallet wrappers since they only need to secure the load in two or three places. Some pallet strappers can complete two to three pallets per minute, depending on the type of load and the number of straps.

🡢 More economical:

Strapping is also cheaper than stretch film. It uses less material to secure and comes in various break strengths for different load needs.

🡢 Environmentally friendly:

A pallet strapping machine uses fewer consumables, producing less waste. Many strapping consumables are also made from recycled materials, making strapping machines more sustainable than other pallet securing methods.

🡢 Better stability:

Pallet strapping machines provide better containment for a heavy load. Because the strap is threaded through the pallet, it keeps the items more effectively secured.

The strapping consumable also offers better resistance than plastic stretch film. In addition, the operator can adjust the tension on a strapping machine for different load requirements.

Mosca International

Mosca International

America

America

Asia

Asia

Australia

Australia

中国

中国

Deutschland

Deutschland

Suomi

Suomi

France

France

Great Britain

Great Britain

Indonesia

Indonesia

日本

日本

Malaysia

Malaysia

Mexico

Mexico

Nederland

Nederland

Polska

Polska

España

España

ประเทศไทย

ประเทศไทย

Magyarország

Magyarország