6 Challenges the Corrugated Box Industry Faces

Below are some of the challenges you may be facing.

1. Supply Chain Issues

Supply chain issues have impacted many industries and the corrugated box industry is no exception. Every component needed to run a plant is affected, from paper to glue to strapping materials. For some products, lead times have increased from days to weeks. These supply chain issues have required corrugated box companies to adapt by evaluating demand from customers and then providing tailored solutions for them.

2. Increase in Raw Material Prices

Another major challenge for the corrugated box industry are the increasing costs of raw material used to make corrugated packaging. The reason: many industries are competing for raw materials, and the supply is depleting rapidly. Due to the increase in demand and the drop in available supply material, the cost has risen accordingly. Another reason are the increasing energy costs at paper mills. These higher production costs have reached companies in the corrugated box industry and force them to spend more on raw materials like kraft paper. This causes prices throughout the next part of the supply chain to increase as well.

3. Demand for Custom Packaging

The demand for custom packaging is growing rapidly. This is partly due to the demand of varied shapes in the carton packaging market where custom packaging has become the new norm. Though the demand for custom packaging is good, it can pose challenges for those not equipped to handle it.

Corrugated box manufacturers need to be capable of swiftly adapting to customers’ changing needs to stay competitive. As a corrugated box manufacturer, you have to be able to produce innovative custom packaging efficiently while keeping costs as low as possible per package. A solution: Maximize the folder gluer’s productivity by optimizing your production capabilities and installing quality folder gluer packaging equipment.

4. Small or Single Orders

There is also an increasing demand for orders that do not meet a manufacturer’s previous minimum quantity requirements. Whether a customer requests 100 boxes or one, you need to be able to provide what they need and adapt quickly. To ensure your business’s longevity in the corrugated box industry and stay competitive, you need to remain flexible.

If you currently don’t offer your customers the option to place an order without minimum quantity requirements, you may want to implement this option to surpass the competition and retain your customers. Though they may not seem worthwhile, small or single orders can help keep you in business.

5. Equipment Downtime

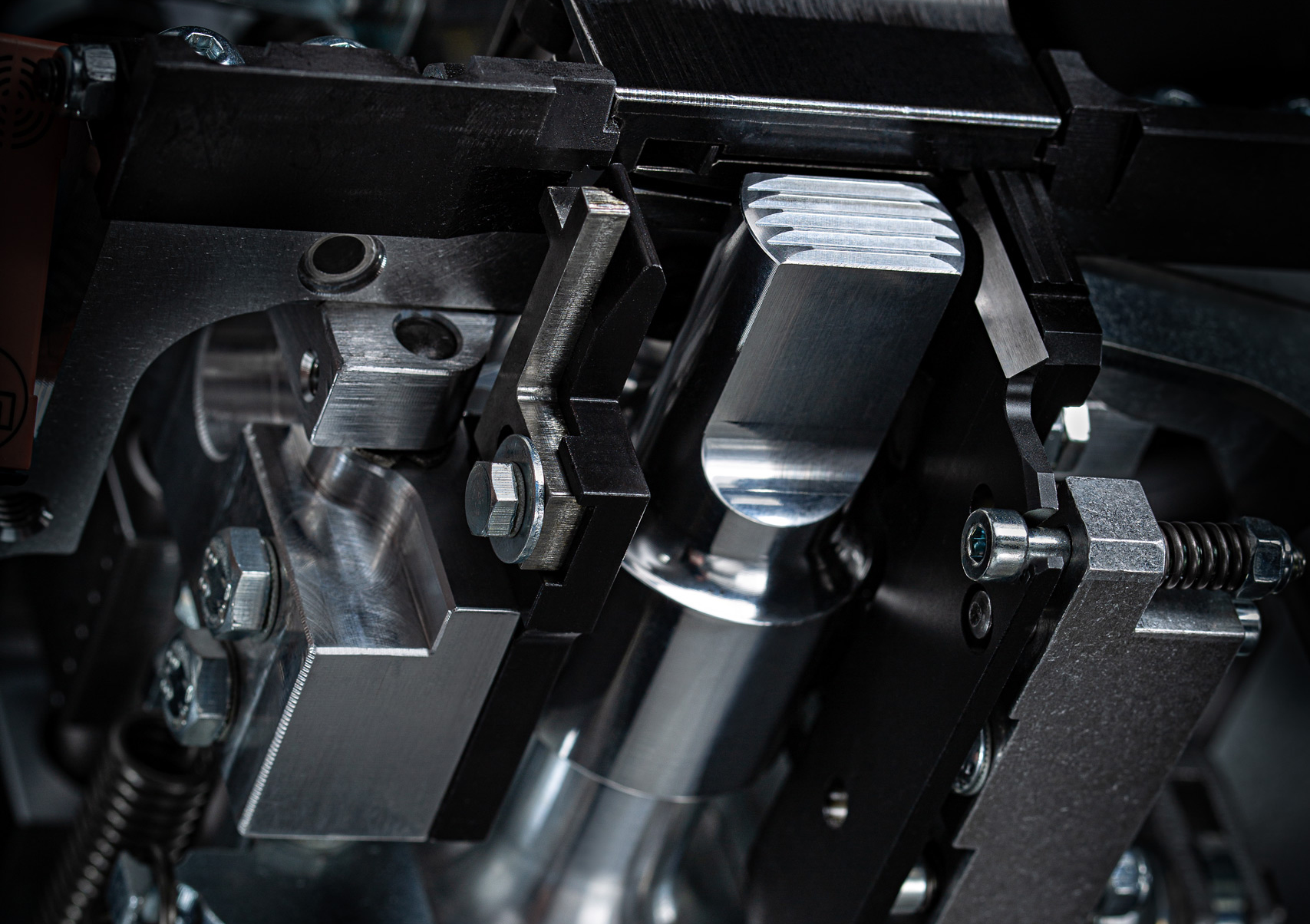

Due to the substantial volume of output the corrugated box industry produces daily, the industry is very dependent on reliable equipment, as it is sensitive to productivity numbers. As a result, unexpected equipment downtime can be costly. Equipment downtime could for example be caused by mechanical failures.

The solution: Be sure to keep up with preventative maintenance to minimize downtime. The proper maintenance should keep your equipment in ideal working condition so you can continue meeting your objectives. Mosca has a portfolio of end-of-line systems that can reduce downtime, allowing you to meet and exceed performance goals.

6. Last-Minute Orders

The corrugated box industry also faces the challenge of receiving last-minute orders. This is one of the most difficult ongoing issues for manufacturers. While last-minute orders can mean more business and revenue, they also bring tighter deadlines and more stress for your team.

Though these orders are placed with little time to fulfil them, the customer’s requirements and expectations are still the same. You need to provide high-quality boxes that meet their needs in a timely manner. To successfully manage these orders, incorporate a high-performance machine line into your production setting that has the power to produce and package more boxes at a faster speed with fewer packing personnel.

The Good News About Corrugated Box Trends

While the corrugated industry is doing its best to tackle these pressing issues, there is good news for their sector as well. There are two packaging trends which could drive growth within the industry:

- Increase in e-commerce: One of the most promising corrugated box trends is the big increase in the e-commerce industry. Businesses are going and selling online more than ever before, and there is a huge boost in demand for corrugated packaging.

- Demand for sustainable packaging: Corrugated cardboard is sustainable, and there is currently an increasing demand for sustainable packaging and solutions like strapping.

Looking Towards the Future

Despite its challenges, the corrugated industry is positioned for growth in the coming years. Though companies may have to adjust how they do business, there are a lot of business opportunities, especially if you are flexible and overcome the challenges the industry is facing. To stay ahead of the competition and continue growing your business, it’s essential to have the right equipment for the job, such as strapping machines designed specifically for the corrugated industry.

Mosca International

Mosca International

America

America

Asia

Asia

Australia

Australia

中国

中国

Deutschland

Deutschland

Suomi

Suomi

France

France

Great Britain

Great Britain

Indonesia

Indonesia

日本

日本

Malaysia

Malaysia

Mexico

Mexico

Nederland

Nederland

Polska

Polska

España

España

ประเทศไทย

ประเทศไทย

Magyarország

Magyarország