-

Ratkaisut

-

Käyttötarkoitus

- Käyttötarkoitus

-

Vannehtiminen

-

Niputus

-

Käsittelyapu

-

Tuotteen / kuormalavan sidonta

-

Virtuaalinen näyttely

- Virtuaalinen näyttely

-

MOSCA-näyttely Intralogistiikka

-

- Palvelut

- Yhtiö

- Kompetenssit

- Mosca International

Niputus

Strapping is ideal for combining loose goods that are not packed in a box into a product bundle: from newspapers and magazines to rugged items like wooden planks, metal poles and plastic or aluminum tubes, to cables, sleeves, tiles or stone blocks. Even for large parts that are simply too bulky for cardboard, strapping offers a material-saving, secure alternative to secondary packaging.

If you bundle according to quantities, you quickly get an overview of the total number of your articles because larger units are more easily manageable. Even if you also wrap the individual bundles in a box for transport or storage, you have a clear additional benefit: whole bundles are always quicker to move or process than small single items. Taking a look at the production line reveals further advantages. If you combine individual items into larger units – which ideally have the same dimensions and shapes – they can be more easily stacked and conveyed.

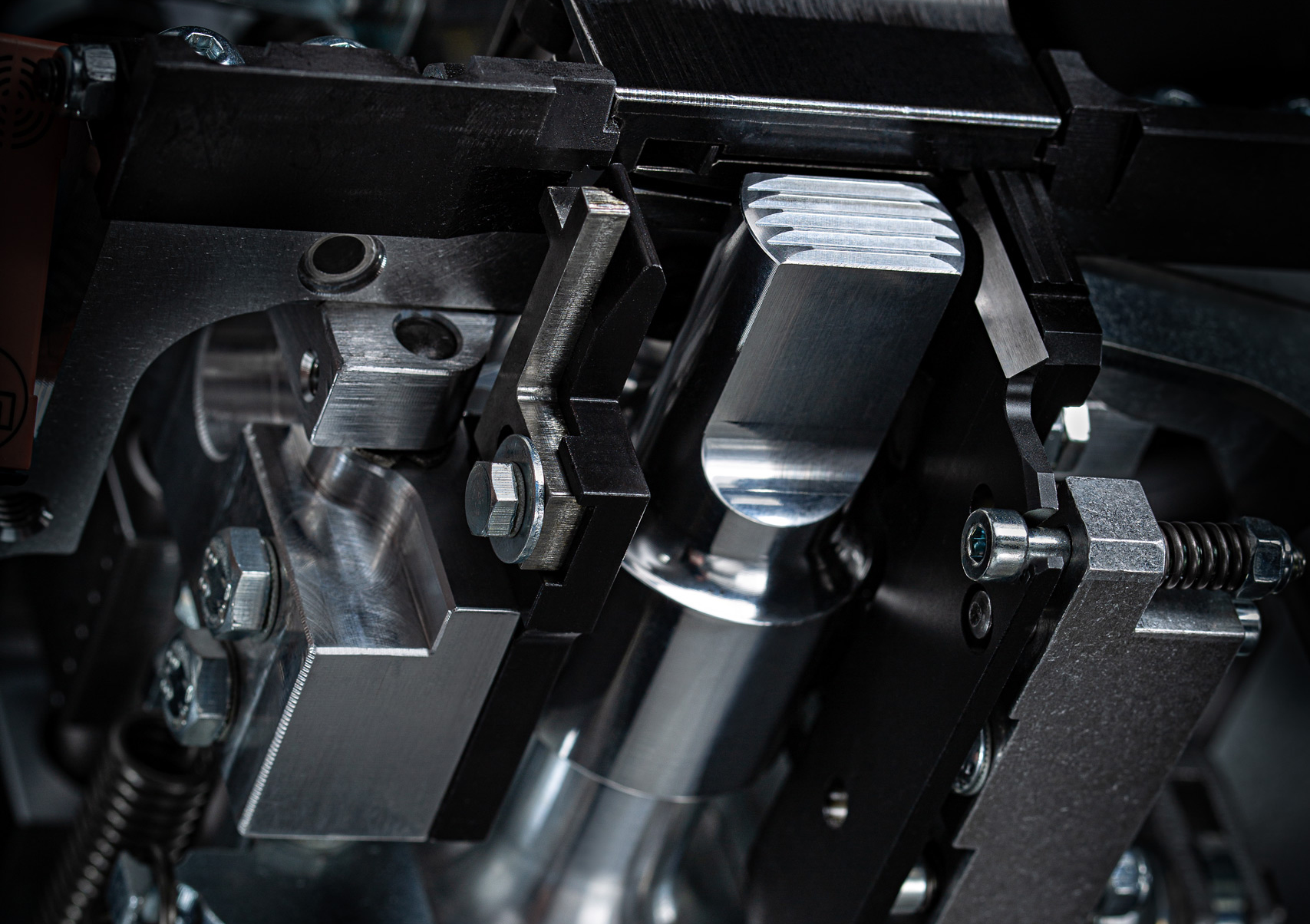

Process reliability and maximum uptime

With our strapping machines, you can bundle your products quickly, securely and with minimal use of materials. Because we know how important reliable processes are for successful operations, our machines work dependably and with maximum availability.

Depending on the type of item you want to bundle, you can choose between straps made from PP, PET or the biocompatible plastic PLA. PP straps are ideal for lighter weight items whereas we recommend PET straps for securing heavy, robust products for transportation. PLA strapping is suitable for many applications and is particularly appropriate if the rest of the packaging material has been put together with a view to its sustainability.

Gentle is at times

Thanks to a special, particularly “soft” setting, our strapping machines can also handle delicate goods. This enables you to safely assemble even fragile items into larger units without damaging surfaces or edges.

Mosca's road to the future!

Mosca International

Mosca International

America

America Asia

Asia Australia

Australia 中国

中国 Deutschland

Deutschland Suomi

Suomi France

France Great Britain

Great Britain Indonesia

Indonesia 日本

日本 Malaysia

Malaysia Nederland

Nederland Mexico

Mexico Polska

Polska España

España ประเทศไทย

ประเทศไทย Magyarország

Magyarország