-

Solutions

-

Application Solutions

- Application Solutions

-

Closing

-

Bundling

-

Handling Aid

-

Load Securing

-

Product Solutions

- Product Solutions

-

Machines

-

Systems

-

Strapping

-

Integrated Solutions

-

Strap Solutions

- Strap Solutions

-

PP Strapping

-

PET Strapping

-

Eco Strapping

-

- Services

- Company

- Competences

- Mosca International

Machine Class Concept

In a class of its own: the right machine for every need

Strapping has many facets – a fact that is reflected in our offering. Our machine portfolio extends from universal devices with a broad application range up to fully automatic high-performance machines that can be integrated into any higher-level automation line, as required.

Depending on your industry, your products and the required level of performance, we offer you semi-automatic, automatic or fully automatic machines, all of which share one thing in common. They all feature the same top Mosca quality, guaranteeing you outstanding strapping results and maximum availability.

Three classes – all top quality

Across our portfolio, we divide our products into machine classes I, II and III. All models are available ex factory with CE conformity. Each class is defined by the degree of automation and the increase in the technical capabilities and performance of each machine.

Products in Machine Class I are entry-level models primarily intended for users who do not do a great deal of strapping but are dependent on high availability the moment they need the machine.

Products in Machine Class II can be either automatic or fully automatic and are tailored to the needs of users who do a lot of strapping and rely on fast, reliable processes.

Machine Class III consists exclusively of high-end models that are fully automatic with top performance and already comply with the requirements of industry 4.0. They are fully network compatible and can be controlled from anywhere via a computer or mobile device, as required. This even makes it possible to carry out online remote maintenance from Waldbrunn, for example. In addition, machine status can be read with just a few clicks and software updates directly accessed via the network. Simple and convenient, this is an additional service that we are pleased to offer you.

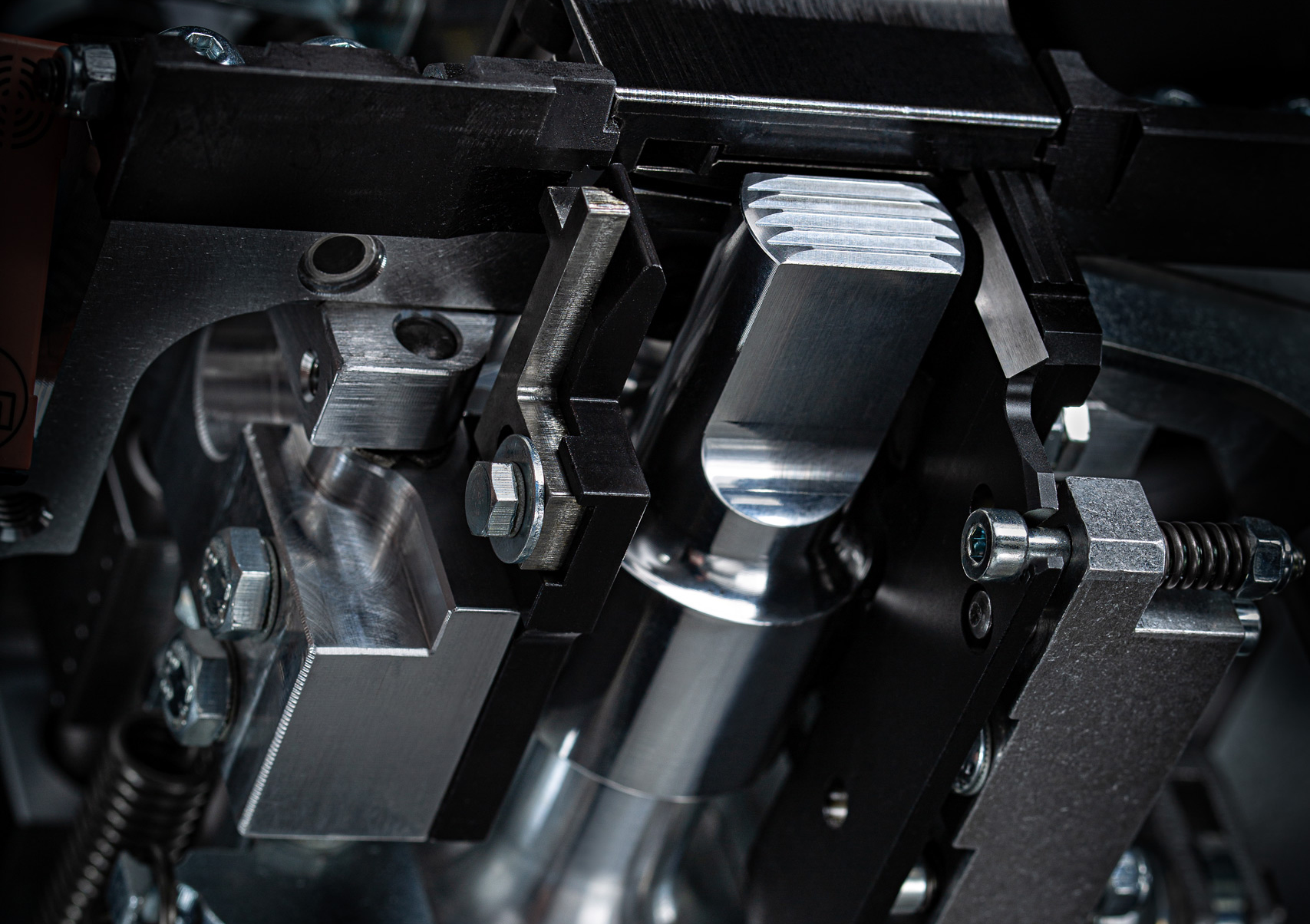

Unique technology with more efficiency

All products in Machine Classes II and III are equipped as standard with our proprietary Mosca ultrasound technology SoniXs, which is unique in the strapping industry. SoniXs machines require no warm-up time and therefore work particularly efficiently. The SoniXs aggregate only consumes power at the moment the straps are welded together using high-frequency vibration. Thanks to the low operating temperature, there is no build-up of excess residue, meaning that SoniXs technology works with particularly low emissions, high reliability and sustainability. Cooling under joining pressure makes the weld extremely durable.

The evolution of strapping – a new generation of machines

From Machine Class II upwards, our customers can also benefit from our modular design principle and the simplified Standard 6 strap path. The Standard 6 strap path can be disassembled without tools and put back together again just as easily in a few steps. This greatly simplifies maintenance and cleaning of the machinery.

The modular design method is based partly on our functional shared component concept, in which important core components of the EVOLUTION series are standardized. These include for example the aggregate, the dispenser, the feeding unit, strap magazine and strap guide frame. Constantly developing this concept enables us to provide our customers with better service because we can assemble all elements particularly quickly and efficiently. Perhaps even more importantly, it enables us to offer top Mosca quality at attractive prices.

Mosca's road to the future!

Mosca International

Mosca International

America

America Asia

Asia Australia

Australia 中国

中国 Deutschland

Deutschland Suomi

Suomi France

France Great Britain

Great Britain Indonesia

Indonesia 日本

日本 Malaysia

Malaysia Nederland

Nederland Mexico

Mexico Polska

Polska España

España ประเทศไทย

ประเทศไทย Magyarország

Magyarország