-

Solutions

-

Application Solutions

- Application Solutions

-

Closing

-

Bundling

-

Handling Aid

-

Load Securing

-

Product Solutions

- Product Solutions

-

Machines

-

Systems

-

Strapping

-

Integrated Solutions

-

Strap Solutions

- Strap Solutions

-

PP Strapping

-

PET Strapping

-

Eco Strapping

-

- Services

- Company

- Competences

- Mosca International

Responsible Production

“Responsible Production” reflects the importance we attach to sustainability. It means that we take responsibility not only for our own products, for the environment and the region, but also for our customers and employees. “Responsible Production” has become part of your company philosophy.

GET Inside: Our label for sustainable cutting-edge technology

This is the reason for introducing a qualification marking: our latest strapping machines, which operate particularly efficient and sustainable through the use of cutting-edge technology, can now be identified at a glance. They bear a green and blue label reading “GET Inside”, which is short for “Green Efficiency Technology Inside”. To be awarded this label, the machines need to fulfil a number of criteria:

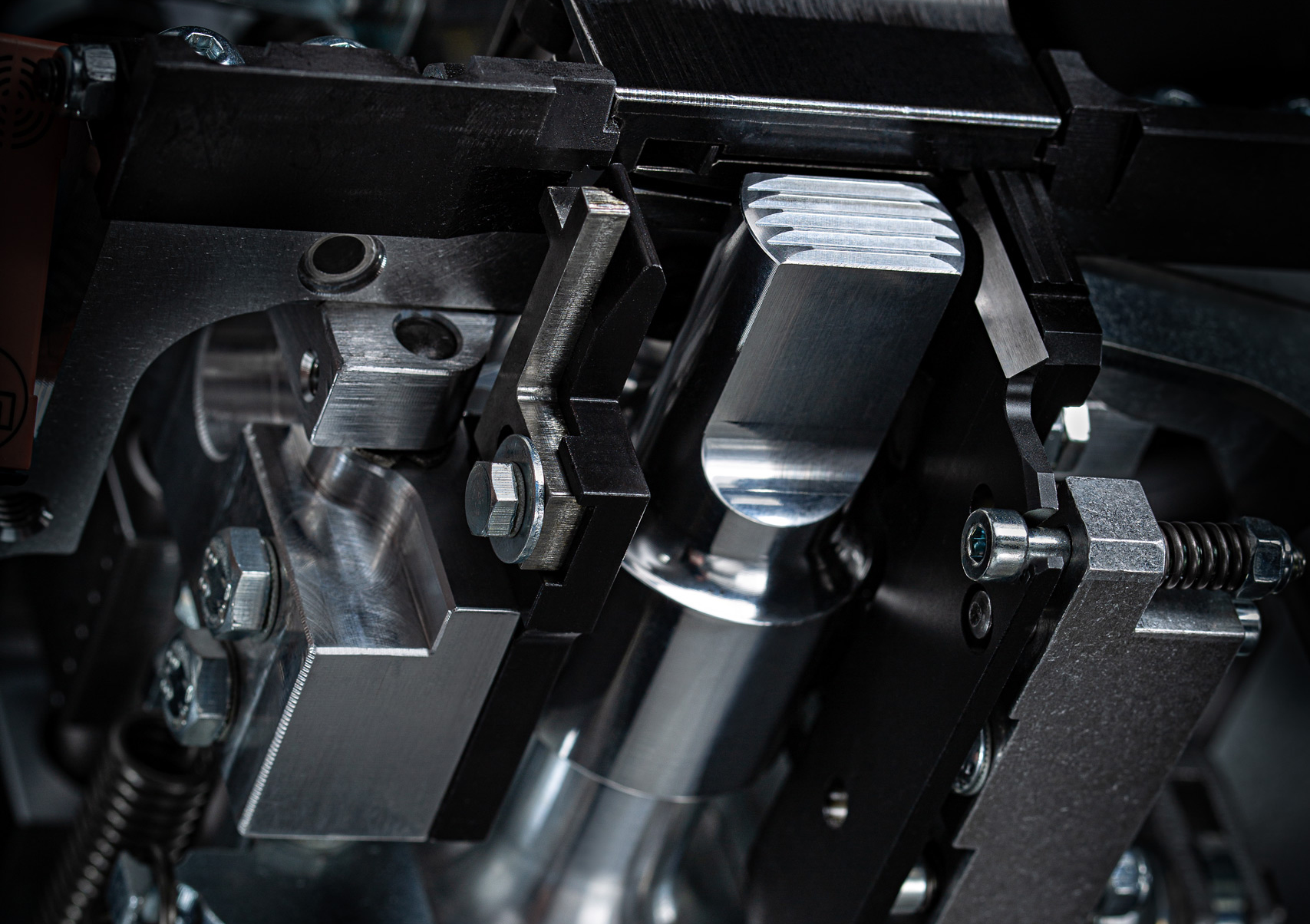

- Ultrasonic sealing technology

- Wear- and maintenance-free drives

- Electrics instead of pneumatics

- Carbon-neutral straps

Fast and safe thanks to ultrasonic

The integrated SoniXs sealing head saves energy by using ultrasonic welding to join the band ends together, rather than the traditional heat-bonding process. At the same time, this technology has a longer working life, is quieter during operation and creates zero emissions. In comparison with machines using heat-bonding sealing heads, it offers up to 50 % longer working life while the cost of sealing components is reduced by up to 80 %. It is also just 25 % as loud in operation as conventional machines. As a Mosca patented product, this sealing head perfectly expresses our concept of sustainability.

Wear- and maintenance-free drives

We have been using wear-free direct drives for our strapping heads since the early 1990s. This technology not only reduces the need for service-intensive mechanical components, but also guarantees quiet operation with minimal friction. At the same time, the machines are almost entirely wear- and maintenance-free. Thanks to their high performance they are also extremely energy efficient.

Electrics instead of pneumatics

Energy-intensive pneumatic and hydraulic drives are increasingly replaced with electric systems to generate the compression force needed by pallet packing presses, or to feed edge protection around corrugated cardboard stacks during strapping. As a result, the strapping machines save resources by working faster, more safely and more energy efficiently.

Carbon-neutral straps

Our PET straps are “green”. They are made from 100 % recycled plastic bottles (bottle flakes), produced in one of the most modern plants in Europe. The energy used in production is generated by solar panels on the factory roof. After use, the straps can easily be recycled again. According to information provided by the recycling service provider Interseroh, the use of recycled materials saves about 85 % of CO2 emissions compared to the primary process. In terms of the production of new granulate materials, this translates into a saving of 2.5 metric tons of CO2 per metric ton of material produced. Aggregated over an entire year of production at Mosca, this is equivalent to saving the same amount of CO2 as is filtered out of the air by a 500-hectare forest.

GET inside for the future

Responsible Production refers both to our own production processes and to those of our customers. Thanks to the relevant technologies and machines, both are more energy-efficient, safer and of a higher quality. We constantly monitor all production factors to improve their efficiency while reducing their environmental impact. In the long run, it is intended that all Mosca products will fulfil the criteria of the GET Inside label. This is what we are committed to.

We hope that, in the future, it will not just be our portfolio that satisfies the criteria of the label, but that these criteria become industry standards in their own right.

Mosca's road to the future!

Mosca International

Mosca International

America

America Asia

Asia Australia

Australia 中国

中国 Deutschland

Deutschland Suomi

Suomi France

France Great Britain

Great Britain Indonesia

Indonesia 日本

日本 Malaysia

Malaysia Nederland

Nederland Mexico

Mexico Polska

Polska España

España ประเทศไทย

ประเทศไทย Magyarország

Magyarország