Strapping machine specialist Mosca and stretch wrapping expert Movitec share the same focus: Fully automated solutions for fast and reliable securing of goods for transport at the end of the packaging line. Mosca's acquisition of Movitec became official on 18.03.2021 at a contract signing at Movitec headquarters in Alcoletge, Spain, which took place in compliance with COVID restrictions. Mosca CEO Timo Mosca says: “Our subsidiary, Mosca Direct Spain, has been working successfully with Movitec on a project basis for several years and it became clear that we have a lot in common, from the highest quality standards and comprehensive service packages, to our operating methods and structures.” Yet the two companies are not in direct competition with each other. While strapping ensures optimal stability of the product bundle, the focus of stretch wrapping is on protecting goods from external influences such as dust, moisture or dirt. Adrian Ritzhaupt, Group Director Commercial & Service at Mosca, explains: "Of course, we currently serve some of the same markets, but this overlap only accounts for a small share of our respective sales volumes. The merger offers great potential to open up new markets for both companies and enables us to provide more comprehensive solutions to our customers."

Movitec co-founder Victor Teixiné is also committed to the merger: "As part of the Mosca Group, we have the opportunity to benefit from the well-established and proven sales and supply chain structures of a global expert. At the same time, we are excited about bringing together the best of both worlds in end-of-line technology and working together to accelerate the development of innovative solutions." Victor Teixiné will continue to oversee Movitec as the managing director and nothing will change for the stretch wrapper manufacturer's 40 or so employees. Processes and customer relationships will also remain unchanged.

Complete systems – sustainable and cost-efficient

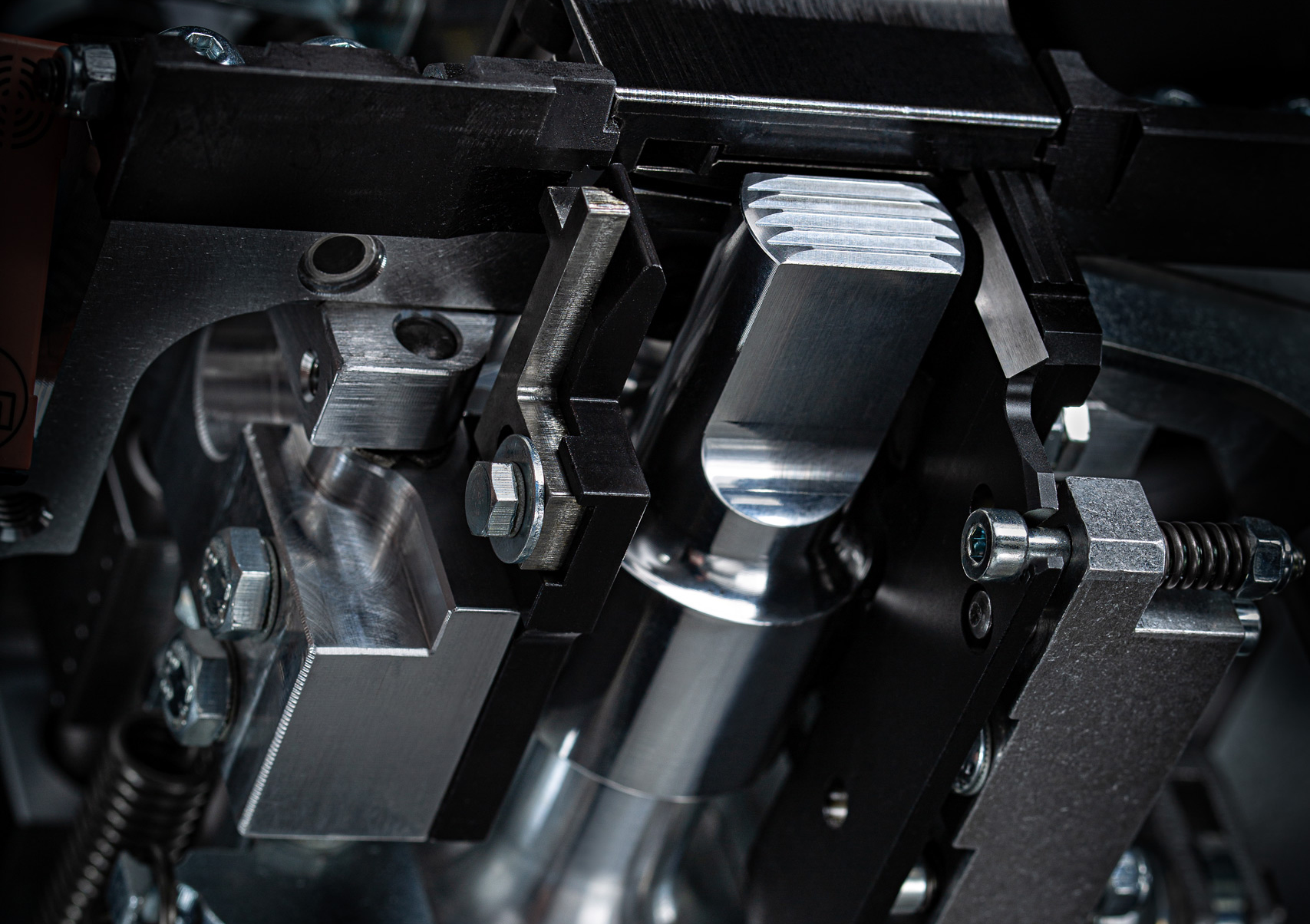

As a result of the acquisition, Movitec will become an independent brand within the Mosca Group. Movitec stretch wrappers are currently used in fully automated applications and, thanks to their ring wrapping technology, they offer exceptionally high throughput of up to 160 pallets per hour. Movitec solutions are most often utilised in the food, agricultural and pharmaceutical industries. Mosca strapping solutions, on the other hand, are mainly found in the corrugated cardboard, paper and logistics industries.

In many industries, complete systems consisting of strapping technology and stretch wrappers are rarely used because, among other things, customers are reluctant to purchase two systems. But Mosca and Movitec have worked together in recent years to successfully plan and install end-of-line systems for the paper processing industry. The combination of both processes is especially useful when products require secure bundling on a pallet and need to be effectively protected against environmental influences. This can be the case, for example, when food products or other sensitive goods are stacked on pallets for transport. Strapping provides the necessary stability and thereby significantly reduces the amount of plastic stretch film required to protect the products. Pay-per-use operational models could be used in the future to make applications like these more cost-efficient and attractive to customers. With this concept, customers only pay for the actual use of the combined system and can save the cost of purchasing the machinery.

Timo Mosca: "In addition to the possibilities of digitalisation, we are continuing to focus on sustainability." Mosca has been using eco-friendly materials for years in the production of its strapping materials. For example, only recycled materials are used to manufacture PET strapping. “We would now like to bring the knowledge we have gained from our own developments to Movitec. Working with the Movitec experts, we will also be looking for potential ways to optimise the eco-sustainability of stretch wrapping as a technology in the next few years.”

Mosca International

Mosca International

America

America

Asia

Asia

Australia

Australia

中国

中国

Deutschland

Deutschland

Suomi

Suomi

France

France

Great Britain

Great Britain

Indonesia

Indonesia

日本

日本

Malaysia

Malaysia

Mexico

Mexico

Nederland

Nederland

Polska

Polska

España

España

ประเทศไทย

ประเทศไทย

Magyarország

Magyarország