One of the highlights at the Mosca display at IFFA is the live demonstration of an application for the meat industry. Several plastic boxes packed with meat products are fixed to a dolly for safe, non-slip transport. The trolley is manually raised on a 150 mm high ramp where an Evolution SoniXs MS-6 is installed. The machine double straps the dolly and stack of boxes before the dolly is lowered off the ramp. This example demonstrates how the right strapping solution can seamlessly and cost-effectively link production and downstream transport. "The sample application at the Mosca exhibition stand shows a layout that perfectly meets food industry needs," explains Mosca GmbH CEO Timo Mosca. "Our machines can be easily integrated into existing processes as a means of optimizing production."

One of the key advantages of the Evolution SoniXs MS-6 for the food industry is the side positioning of the sealing unit. This layout effectively protects the unit from falling debris during processing and reduces maintenance time. This versatile strapping machine can be integrated into manual or fully-automated operations. Thanks to the available interfaces, this model can easily be integrated into existing production lines.

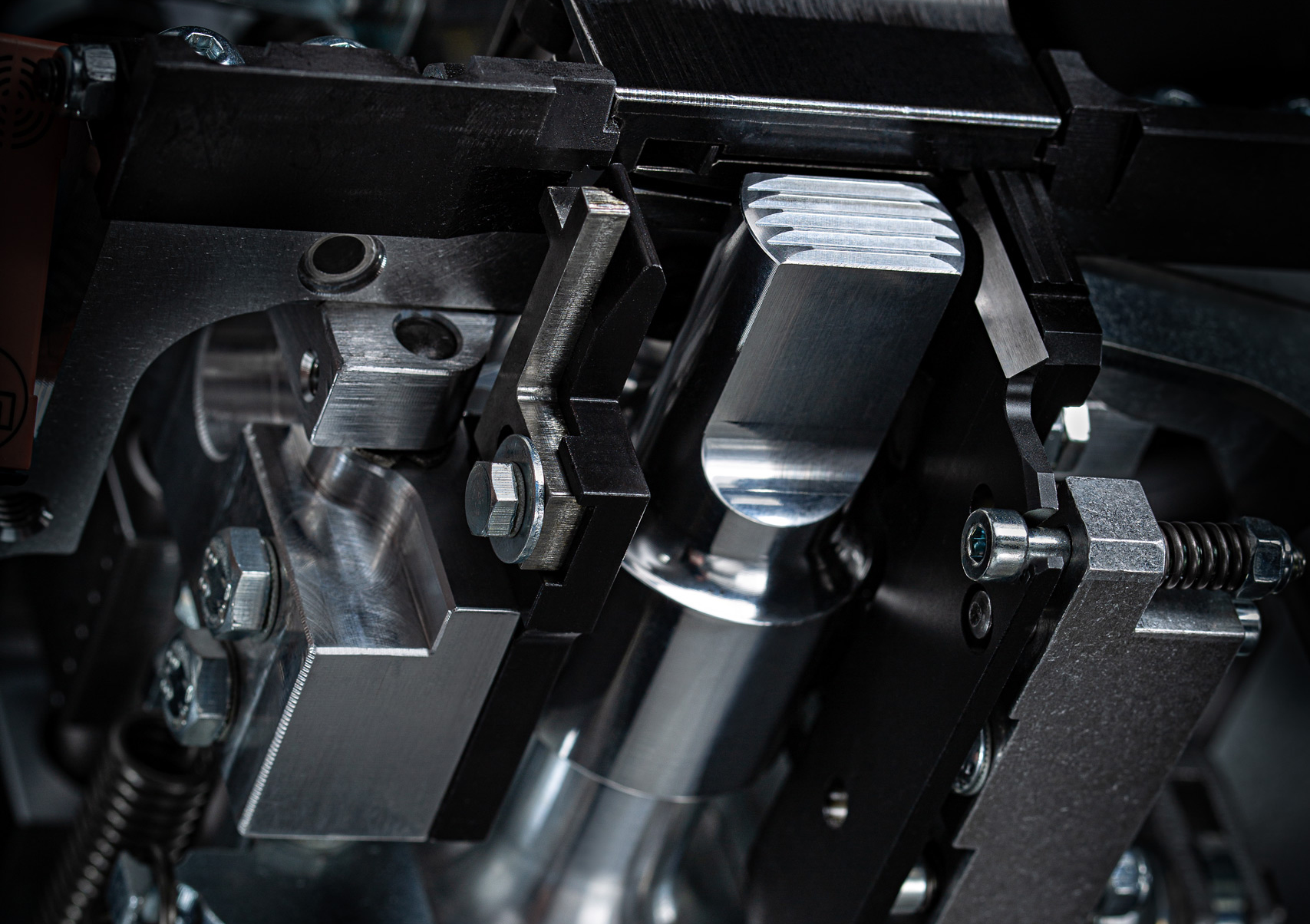

Patented ultrasonic sealing unit ensures hygienic conditions

Both the Evolution SoniXs MS-6 and Evolution SoniXs MP-6 VA on display at IFFA feature Mosca’s own ultrasonic sealing units. This makes them ideal for processing open food products. Conventional heat-welding units use heat to seal the strap ends. This technology can produce harmful fumes that, in the worst case, come into contact with the food. This risk is completely eliminated with an ultrasonic sealing unit. "Clean and safe end products are a top priority in the food industry," explains Mosca GmbH CEO Alfred Kugler. "The machines we are presenting at IFFA clearly meet these demands."

High-quality stainless-steel model available in several versions

The Evolution SoniXs MP-6 VA wins over food manufacturers with its choice of material. This machine is made with stainless steel to ensure extremely hygienic production conditions. The Evolution SoniXs MP-6 T-VA table model straps up to 50 packages per minute. The version equipped with a roller conveyor (Evolution SoniXs MP-6 R-VA) straps up to 35 packages per minute. At low load, operators can easily slow down the machine from maximum to Eco-speed. Thanks to the adjustable control panel, both strapping machine versions can be operated in tight spaces. The Evolution SoniXs MP-6 R-VA can also be integrated into fully-automated lines.

Mosca International

Mosca International

America

America

Asia

Asia

Australia

Australia

中国

中国

Deutschland

Deutschland

Suomi

Suomi

France

France

Great Britain

Great Britain

Indonesia

Indonesia

日本

日本

Malaysia

Malaysia

Mexico

Mexico

Nederland

Nederland

Polska

Polska

España

España

ประเทศไทย

ประเทศไทย

Magyarország

Magyarország