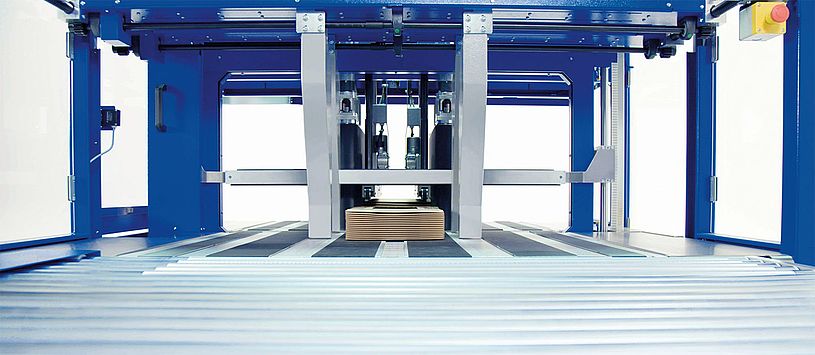

The manually operated CE-compliant strapping machine can strap complex four or six -point folding cartons, made possible by product alignment on up to six sides. It boasts comprehensive network communication, as well as formula storage through a touch panel, which allows the machine to operate immediately without additional safety measures.

The UCB straps folding carton stacks with polypropylene strap in widths ranging from 5 to 12 millimetres. To operate, the user simply removes the folding cartons from the folder gluer, places them crosswise, and feeds them into the UCB. The machine's conveyor system guides the stack inside and aligns it on five sides. The automatic strapping and machine configuration ensures maximum flexibility, with the UCB adjusting smoothly to packages with a width of 120 to 1200 millimetres.

The symmetrically movable alignment units position the product optimally to the central SoniXs ultrasonic sealing unit. An optional back pusher is available for even more precise six-sided alignment. After the product is fully-aligned to the strapping level, the UCB automatically straps it and moves it forward out of the machine. The machine’s comprehensive networking means that up to 32 single strap or 20 double strap cycles per minute are possible.

Operators can store preset formulas for frequently used products via the touch panel or control desk and quickly retrieve them. The Remote Monitoring Interface (RMI) enables employees to retrieve and monitor the UCB and its current strapping program from practically any device, including smartphones.

In addition to being easy to operate and low maintenance, the machine also includes Mosca’s patented SoniXs ultrasonic sealing unit and brushless DC drives to reduce overall wear.

“The UCB is the first of its kind for the corrugated cardboard industry, which can be integrated into a corrugated cardboard production line with 100% operation reliability,” explains Mosca Direct’s Sales Manager, Rob Toolen. “The automatic cycle rate adjustment (CRA) reduces wear on the machine by enabling the UCB to match the strapping rate to the pace of the operator and the upstream system. The customer can switch the feature on or off. When it is activated, a tool continuously calculates the throughput and regulates the UCB motors accordingly."

As part of the machine's network capability, Mosca specialists can perform routine maintenance on the UCB remotely and assess potential problems. For routine maintenance work on site, the strapping unit can be removed easily using an electromechanical lifting station.

For more information on the UCB or Mosca’s machine offering, please cal one of our expert advisors on 0115 989 0209

Mosca International

Mosca International

America

America

Asia

Asia

Australia

Australia

中国

中国

Deutschland

Deutschland

Suomi

Suomi

France

France

Great Britain

Great Britain

Indonesia

Indonesia

日本

日本

Malaysia

Malaysia

Mexico

Mexico

Nederland

Nederland

Polska

Polska

España

España

ประเทศไทย

ประเทศไทย

Magyarország

Magyarország