Five Production Steps

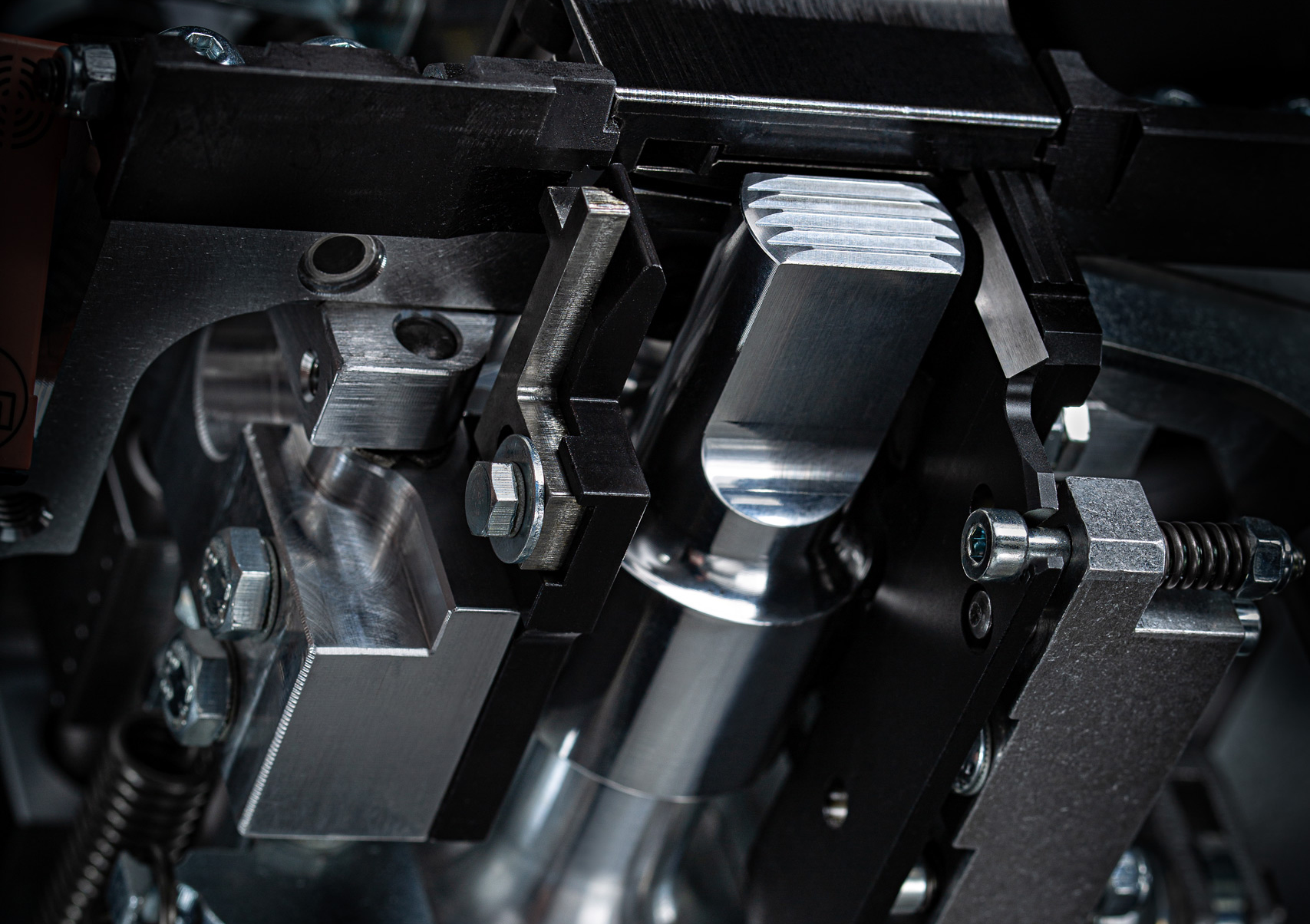

5 steps are necessary to turn polypropylene granulate or polyester flakes into strap: Extrusion, Stretching, Embossing, Fixing and Winding. Needless to say, quality control is also an important part of the manufacturing process. The quality of the incoming raw material is examined, and several strap parameters are tested and documented regularly.

A Code for Every Coil

A label with readable electronic data, the so-called RFID tag, is assigned to every strap coil directly after the winding process. With this unique code, the origin of each roll is traceable which allows us to respond to any deviations, to optimize our production processes and to guarantee a consistently high quality of our strapping material.

Additionally, a system developed by Mosca in cooperation with PSI Automotive & Industry GmbH and the Winckel company provides an opportunity for customers to make use of the RFID tag in their operations: Through RFID gates and the strapping machine itself, information on the tag is read and forwarded to the customer’s ERP system which automatically reorders strap if the material stock drops below a certain pre-defined level.

Sustainability & Resources

Reducing plastic waste is a global challenge. We make our contribution by ensuring that all polyester (PET) strap that is distributed by Mosca is made from recycled plastic bottles. As customers in Germany are encouraged to return empty plastic bottles to supermarkets for recycling, Mosca uses this recycled material – the so-called “bottle flakes” – to manufacture PET consumables in its Muckental plant. In fact, the predominantly green-coloured PET strap is made from 100% recycled material. Any other plastic waste material that is generated during production is shredded and re-used as well.

The use of recycled material significantly reduces the amount of CO2 generated during production. In fact, the utilization of recycled material saves about 85% of CO2 emissions compared to primary processes. The savings made within one year are equivalent to the annual amount of CO2 filtered from the air by a 500-hectare forest.

However, Mosca goes even further when it comes to sustainability: The PET strap production in Muckental is climate neutral as the solar panels on the roof provide more energy than the manufacturing process requires.

Stay updated on the latest news about Mosca strapping technologies by connecting with us on LinkedIn and Facebook using the links below.

Mosca International

Mosca International

America

America

Asia

Asia

Australia

Australia

中国

中国

Deutschland

Deutschland

Suomi

Suomi

France

France

Great Britain

Great Britain

Indonesia

Indonesia

日本

日本

Malaysia

Malaysia

Mexico

Mexico

Nederland

Nederland

Polska

Polska

España

España

ประเทศไทย

ประเทศไทย

Magyarország

Magyarország