-

Solutions

-

Application Solutions

- Application Solutions

-

Closing

-

Bundling

-

Handling Aid

-

Load Securing

-

Product Solutions

- Product Solutions

-

Machines

-

Systems

-

Strapping

-

Integrated Solutions

-

Strap Solutions

- Strap Solutions

-

PP Strapping

-

PET Strapping

-

Eco Strapping

-

- Services

- Company

- Competences

- Mosca International

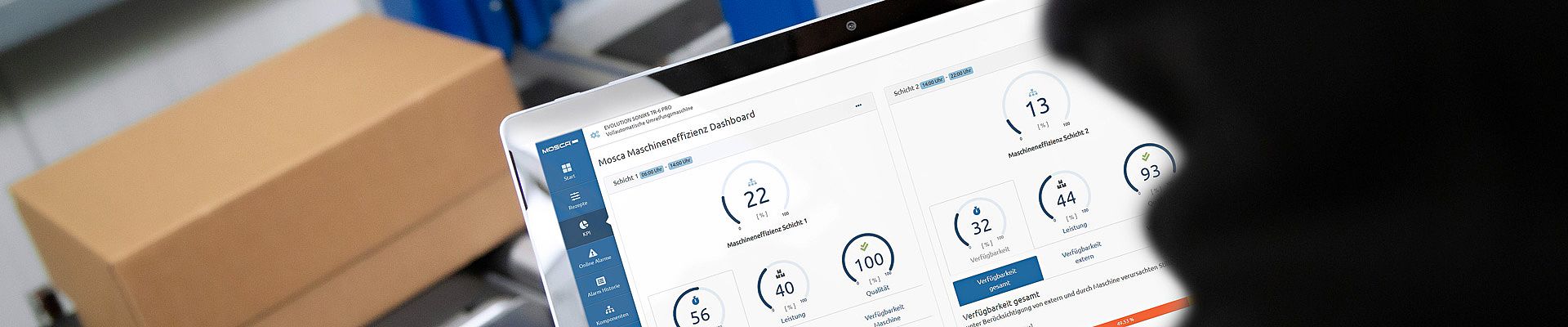

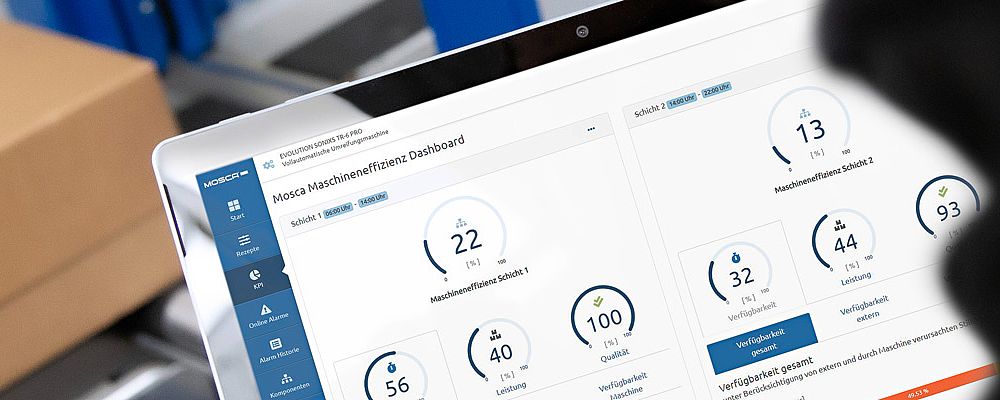

WebHMI

The new generation of MOSCA strapping machines is smart. Based on Machine Class III, we supply strapping machines that can be controlled and monitored via an integrated WebHMI, or web-based human-machine interface. This feature enables you to access all machine-relevant data using a tablet computer or other smart devices.

With WebHMI you get insight into all key performance indicators, including availability, output, quality or strap settings. This enables you to detect potential problems at an early stage. If necessary, MOSCA service teams respond quickly and efficiently to correct errors on the spot – so that your operations can continue uninterrupted.

Visualisations provide a quick overview and allow system assessments that help increase your productivity. For example, you can evaluate the throughput of a machine during morning, afternoon or night shifts. You can also see which strap coil was used along with the machine's strapping performance in operation. Other KPIs can be monitored and strapping recipes can be sent to the machine via WebHMI.

This overview of all machine-relevant data means that optimisation potential can be quickly and easily identified and individually implemented into your operation.

Secure, decentralised data processing is a prerequisite for smart strapping solutions. The compiling of data has no influence on machine functionality because our integrated MOSCA Edge Computing Module (MECM) processes the data separately from the controller. All data required for future digital business models are transferred to a cloud via a gateway.

We use a secure OPC UA interface as the data transfer standard for transmitting data from the machine control system to the Edge Computing Module.

Maximum data security is guaranteed by UL certification (UL 2900-2-2) of the data transmission through our gateway to the cloud.

Mosca's road to the future!

Mosca International

Mosca International

America

America Asia

Asia Australia

Australia 中国

中国 Deutschland

Deutschland Suomi

Suomi France

France Great Britain

Great Britain Indonesia

Indonesia 日本

日本 Malaysia

Malaysia Nederland

Nederland Mexico

Mexico Polska

Polska España

España ประเทศไทย

ประเทศไทย Magyarország

Magyarország