-

Solutions

-

Application Solutions

- Application Solutions

-

Closing

-

Bundling

-

Handling Aid

-

Load Securing

-

Product Solutions

- Product Solutions

-

Machines

-

Systems

-

Strapping

-

Integrated Solutions

-

Strap Solutions

- Strap Solutions

-

PP Strapping

-

PET Strapping

-

Eco Strapping

-

- Services

- Company

- Competences

- Mosca International

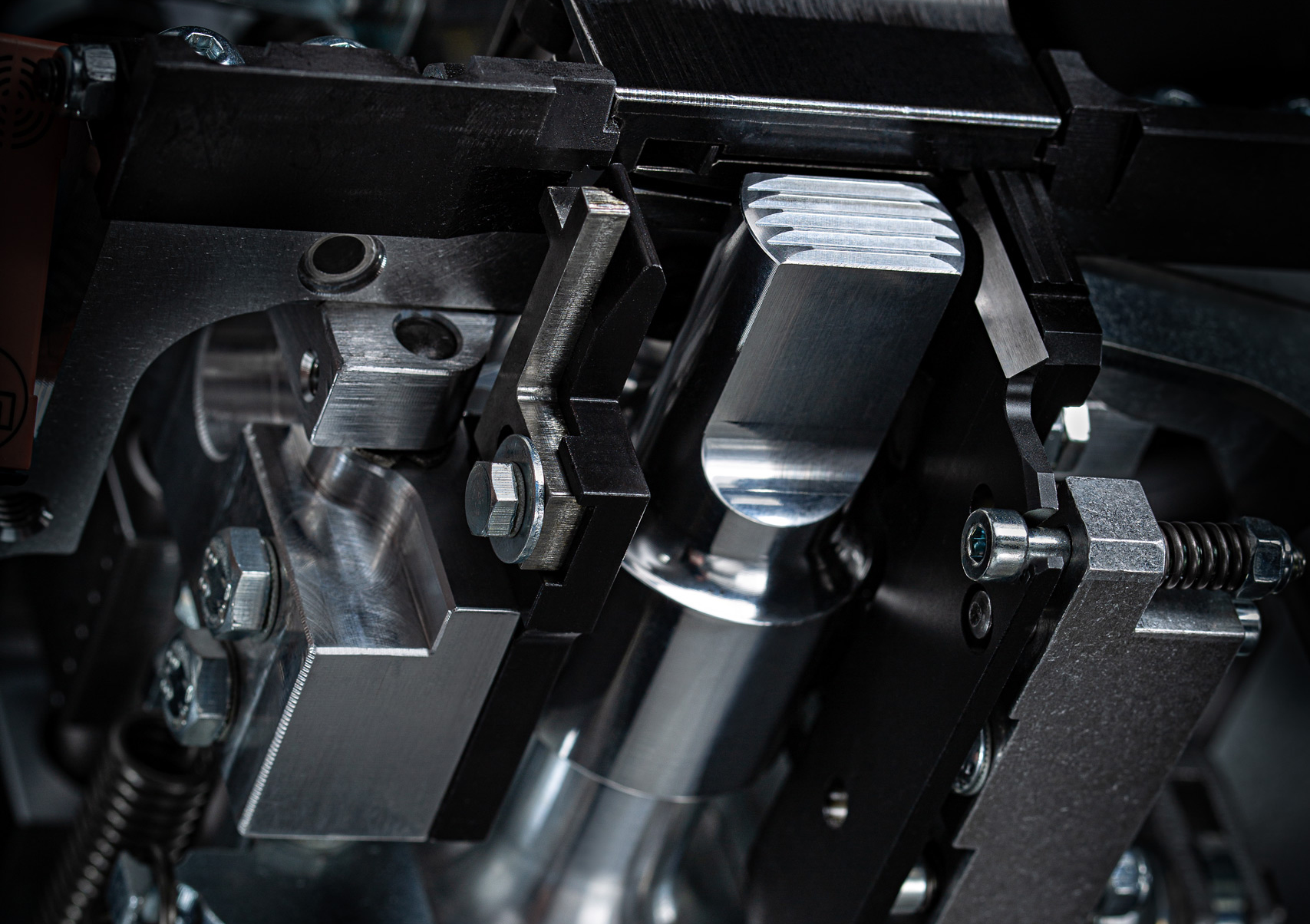

SoniXs Ultrasonic Sealing Technology

Joining the two open ends of the strap loop is decisive in the modern strapping technology: Economical efficiency in terms of Total Cost of Ownership combined with outstanding performance are in demand. With the development of the ultrasonic sealing technology SoniXs, Mosca offers a unique, groundbreaking procedure that meets with these requirements.

Using ultrasonic sealing mechanical vibrations are transmitted under pressure on the ends of the plastic strap compressing them together. A special sonotrode – the heart of the new sealing unit – joins the strap ends extremely strong-consistent, fast and low on emissions, without generating heat. The process controlled system is very operation-friendly, low in maintenance and operates nearly wear-free.

We have also developed the related electronics: thus, the solution is perfectly matched to the respective application.

Economical

The SoniXs technology requires energy only punctually to produce mechanical oscillations just in the actual moment of sealing. This makes it particularly cost-efficient. Thanks to the increased tensile strength, often thinner and / or narrower straps can be used, thus making considerable savings.

Sustainable

No smells, cleaning-intensive melding residues or polluting fumes are produced, as it often happens with traditional heating systems when PET straps are thermally compounded. Low running noises by linear supported parts improve the environment.

Efficient

The complete sealing unit operates exclusively with brushless DC motors. All moveable parts ravel short distances and are linear bearings. This guarantees smooth flow with low friction – and a long durability with less wear and tear. The sonotrode of the ultrasonic sealing unit guarantees maximum tensile strength, so the transported goods withstand even particularly high loads. Plastic straps of Polyester (PET), Polypropylene (PP) and Polylactid (PLA) are suitable for being processed with the ultrasonic technology.

Mosca's road to the future!

Mosca International

Mosca International

America

America Asia

Asia Australia

Australia 中国

中国 Deutschland

Deutschland Suomi

Suomi France

France Great Britain

Great Britain Indonesia

Indonesia 日本

日本 Malaysia

Malaysia Nederland

Nederland Mexico

Mexico Polska

Polska España

España ประเทศไทย

ประเทศไทย Magyarország

Magyarország