-

Solutions

-

Application Solutions

- Application Solutions

-

Closing

-

Bundling

-

Handling Aid

-

Load Securing

-

Product Solutions

- Product Solutions

-

Machines

-

Systems

-

Strapping

-

Integrated Solutions

-

Strap Solutions

- Strap Solutions

-

PP Strapping

-

PET Strapping

-

Eco Strapping

-

- Services

- Company

- Competences

- Mosca International

Liebensteiner Kartonagenwerk GmbH – Precision at high speed

The applications for cardboard protection and packaging are virtually unlimited. The customer base of Liebensteiner Kartonagenwerk GmbH in Plößberg is just as varied. The company relies on strapping machinery from MOSCA GmbH to secure their own goods ready for transport. The newest addition in the Production hall is the brand new high performance UATRI-2 machine.

“The strapping machines meet the varied needs with regard to production speeds and bundling requirements.”

From the smallest box to large corrugated furniture protectors, Liebensteiner produces and delivers the entire range. Beginning in 1968 as a two man company producing small amounts from 10 to 20 boxes, today the company is a large corrugated cardboard business covering all areas in the production of cardboard products.

The customer base in Germany and worldwide is predominantly in the automobile and distribution industries, producers of cosmetics as well as machinery and plant equipment.

Bernhard Schön, son of the original founder has headed the family business for more than 30 years. Meanwhile the 230 strong workforce produces around 60 million square metres of corrugated cardboard a year serving 1,200 customers, each cut and 4-colour printed to individual requirements in batches of up to 100,000 units. Ten cardboard production lines run on a daily basis.

Precise and exact strapping

The full product range of MOSCA GmbH is in use at Liebensteiner; from simple plastic strapping machines like the RO-MP which is suitable for smaller orders and managed manually by an Operator, ranging to fully automatic inline machines like the UATRI and pallet presses.

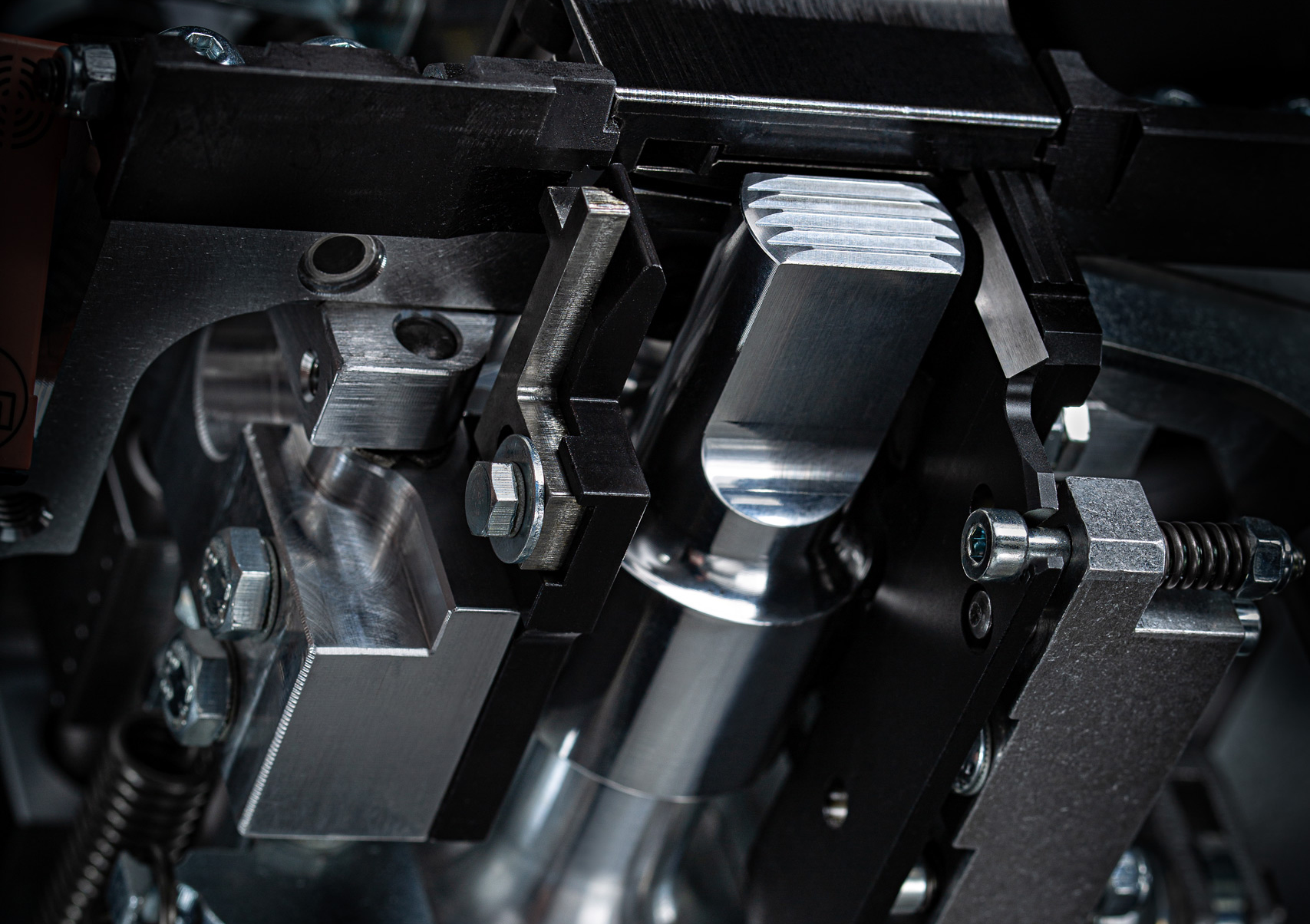

The fully automated UATRI strapping machine was specifically designed for high speed automated lines. Liebensteiner introduced one of the first units as part of a major investment plan in 2009 which has now been installed in Plößberg since February 2010. This high capacity machine is characterised by high productivity, easy operation and increased reliability.

The UATRI-2 has a throughput of up to 30 bundles per minute single or double strapped in perfectly aligned stacks. The pneumatic drives of the previous model have been replaced by cost effective electric motors that are more accurate and offer quieter operation. The integrated alignment station ensures that bundles entering the machine are squared equally on all sides and held in place using a press. Bundles therefore exit the machine strapped uniformly and precisely even at the highest production speeds.

Increased Productivity

Set-up times and downtime are reduced to a minimum thanks to fully integrated automatic processing. The UATRI-2 adjusts to the new bundle dimensions with the aid of online data transfer from the upstream machinery. 2 strap dispensers mean that production is not interrupted for manual strap coil changes. When a coil runs out, the strap is spliced automatically with no break in the production process.

Managing Director, Mr Schön, is impressed by how user friendly the machine is: “Before the new packet dimensions had to be loaded into the computer with each change of product size. With the UATRI-2 this is no longer necessary as the machine automatically adjusts to the new dimensions as the first bundle arrives into the machine.”

“Set-up times are negligible in the machine costing calculation,” Bernhard Schön further points out.

Cooperation with Prospects

Over the years Liebensteiner and MOSCA have developed a close working relationship. Konrad Haner, Technical Director at Liebensteiner, especially commends the after-sales performance of MOSCA GmbH in getting to grips with any problems that may arise. The corrugated manufacturer and MOSCA GmbH work confidentially together to ensure machines run as consistently as possible: Haner gives feedback to MOSCA on the new machines and suggests improvements, MOSCA then responds with relevant adaptations which are then often integrated into new machine series. MOSCA’s engineers are in discussion with Haner regarding the new UATRI-2, aiming to improve the highly developed machine still further in the future.

Mosca's road to the future!

Mosca International

Mosca International

America

America Asia

Asia Australia

Australia 中国

中国 Deutschland

Deutschland Suomi

Suomi France

France Great Britain

Great Britain Indonesia

Indonesia 日本

日本 Malaysia

Malaysia Nederland

Nederland Mexico

Mexico Polska

Polska España

España ประเทศไทย

ประเทศไทย Magyarország

Magyarország