-

Solutions

-

Application Solutions

- Application Solutions

-

Closing

-

Bundling

-

Handling Aid

-

Load Securing

-

Product Solutions

- Product Solutions

-

Machines

-

Systems

-

Strapping

-

Integrated Solutions

-

Strap Solutions

- Strap Solutions

-

PP Strapping

-

PET Strapping

-

Eco Strapping

-

- Services

- Company

- Competences

- Mosca International

Heilbronner Stimme - Ultrasonic sealing technology impresses in practice

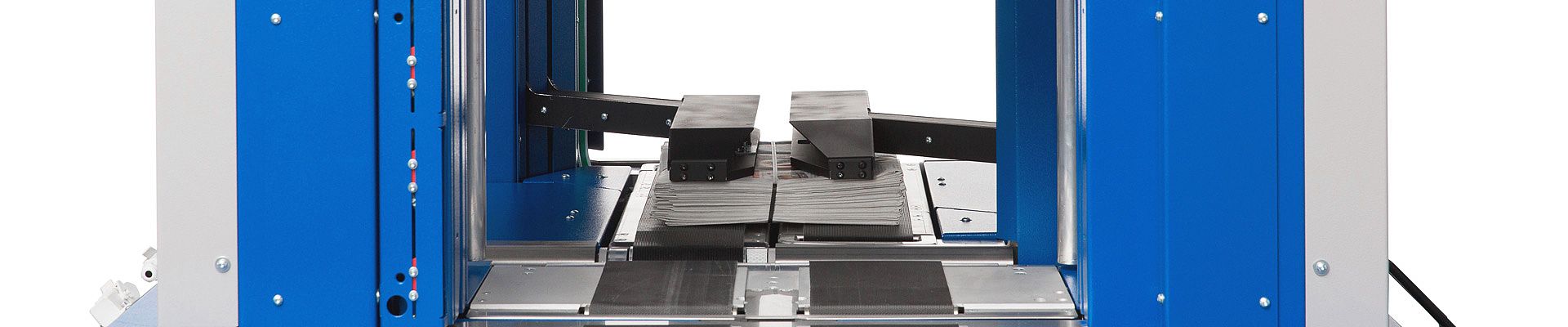

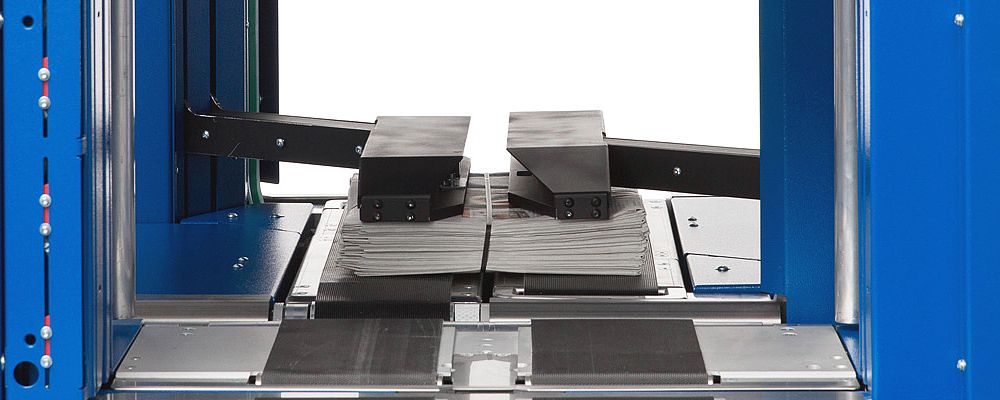

Heilbronner Stimme is a regional newspaper and the only daily paper in Heilbronn, a city in Baden-Württemberg. The publishing house of the Heilbronner Stimme with over 500 employees, issues both the daily papers Hohenloher Zeitung and Kraichgau Stimme in addition to 7 regional editions of the Heilbronner Stimme as well as diverse advertising journals. With a circulation of about 100,000 copies and ca. 240,000 readers daily, the Heilbronner Stimme together with the two other newspapers is the leading daily paper for the economic region Heilbronn, Franken, Hohenlohe und Kraichgau. The newspapers are produced in the so-called Rheinisches Format, automatically stacked for transportation, film-wrapped and finally strapped. “With reference to the strapping machines which we use in our production lines to secure for transport, we have been working together with Mosca GmbH for many years”, comments Hans-Jürgen Müller, head of the press printing at the Heilbronner Stimme. “After Mosca put the ultrasonic sealers on the market, we were quickly convinced of the advantages of this efficient sealing technology and changed over to the newest machine type SONIXS-TAI”. Now, all production lines are equipped with two of these strapping machines, arranged in pairs in succession. They are able to cross-strap up to 40 newspaper bundles per minute inline. A turning device is not necessary. The bundle height, which can vary from 0.5 to 40cm, is read automatically and strap tension is adjusted accordingly.

Efficient, energy-saving and reliable

“The high bundle per minute rate was by no means the only factor to our decision“, continues Müller. “Also higher reliability, less maintenance interventions and lower energy costs were essential arguments.” The electrical heater sealing process can leave sticky residues on the heater blade, which reduces the sealing quality and then requires additional, often unplanned maintenance. There is no fear of that with the ultrasonic sealing technology, failing heating-up times.

However, there are further arguments in favour of the ultrasonic sealing systems: the ultrasonic sealers are comparatively quiet, no smells or fumes emerge at sealing and the method is very economical. Energy is only spent during the actual sealing time. Contrary to the heat-welding system, no special temperatures have to be retained. This allows the realisation of a stand-by-operation at times with low package output. Since the ultrasonic sealing unit is immediately ready for operation, it needs only to be activated when a strap cycle is required.

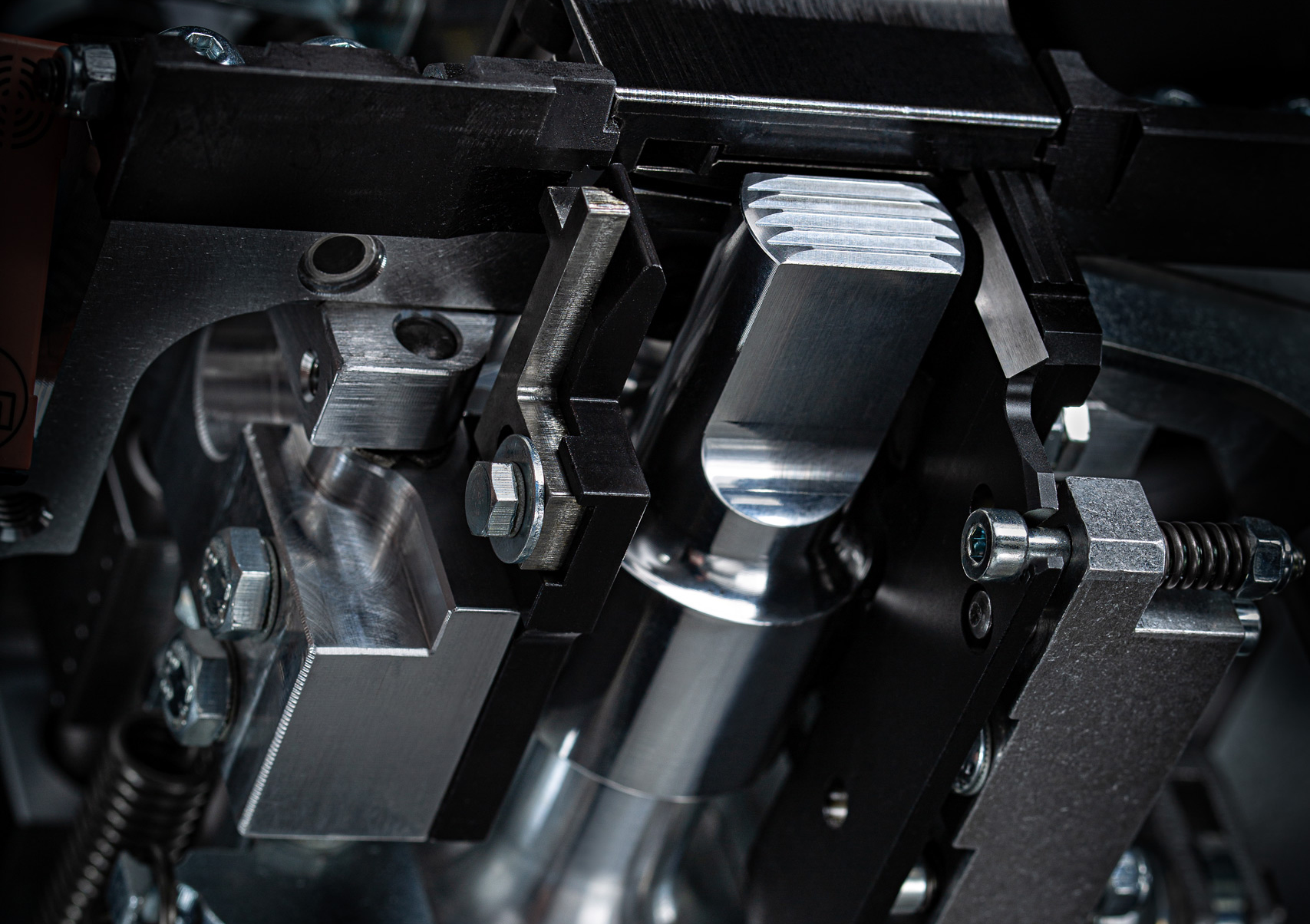

Electro mechanics instead of cost-intensive pneumatics

„Only electromechanical presses and backstops are installed in the strapping machines, that save on the otherwise required energy and cost-intensive pneumatics”, continues Müller. The energy consumption is further reduced by the exclusive use of brushless and virtually wear-free DC motor technology with outstanding high efficiency. The direct drives minimize the number of the formerly common mechanical wearing parts, which also contribute to a regular maintenance requirement.

“In case of service, the sealing units which are designed as modules are dismantled, re-installed or exchanged within a very short time, so that we must schedule only short shut down periods”, states Müller.

Mosca's road to the future!

Mosca International

Mosca International

America

America Asia

Asia Australia

Australia 中国

中国 Deutschland

Deutschland Suomi

Suomi France

France Great Britain

Great Britain Indonesia

Indonesia 日本

日本 Malaysia

Malaysia Nederland

Nederland Mexico

Mexico Polska

Polska España

España ประเทศไทย

ประเทศไทย Magyarország

Magyarország